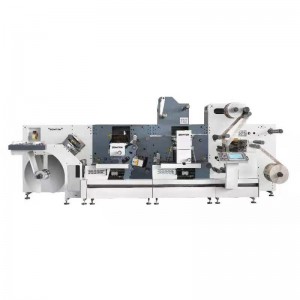

Dragon 320 Flat Bed Die Cutting Machine

| Model | NAGA-320 |

| Mkacepetan kapak | 120M/MIN |

| Jembar kertas efektif maksimal | 330 MM |

| Skacepetan printing layar ilk | 60-100 kaping / min |

| Akurasi pemotongan adesif Akurasi pemotongan IML | ± 0,15 mm ± 0,25 mm |

| Registrasi | Sensor |

| Max panas foil dia | 300 mm |

| Hot foil dipakani arah | 0 dgree/90 dgree |

| Pangaturan lompat foil | Dhukungan dening servo |

| Akurasi register foil | ± 0,15 mm |

| Range panas | 0-200 derajat |

| Area flexo semi rotary 144 Z | 400mm * 320mm |

| Semi rotary die nglereni area 144Z | 400*320 MM |

| Pasokan udara | 0.4-0.6pa |

| ukuran | 11275 * 1510 * 1820 MM |

| bobot | 8000 kg |

| Servo sopir | Panasonic Japan (kalebu unwinding/feeding/rewinding/flexo/die cutting) totallu10 pcs |

| Sistem kontrol | Trio UK |

| PLC | Panasonic Japan Kab |

| Transduser | Panasonic Japan Kab |

| Kontaktor | Schneider Prancis |

| Ngalih udara | Schneider Prancis |

| Nilai | Schneider Prancis |

| Layar tutul | Pingtong Taiwan |

| Web panuntun | BST Jerman |

| Tombol | Schneider Prancis |

| Ora. | produk |

| 1 | DRAGON -320 ngonversi lini produksi kalebu: Konfigurasi dhasar: Unwinding + flat bed hot stamping unit + Rewinder |

| 2 | Unit fleksibel semi rotary |

| 3 | Unit layar sutra |

| 4 | Unit fleksibel semi rotary |

| 5 | Unit foil panas flat bed |

| 6 | Flat bed die cutting unit |

| 7 | Unit nglereni die semi rotary |