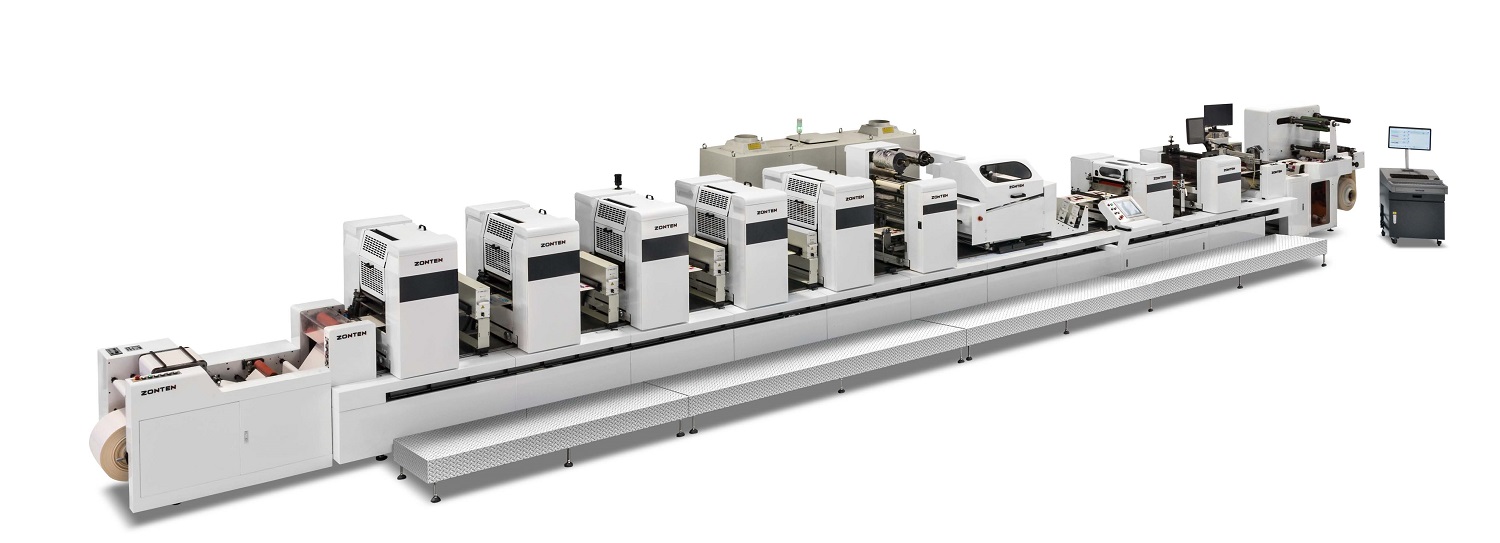

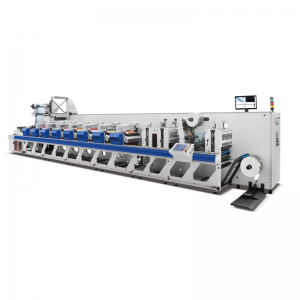

ZTJ-330 Intermittent Offset Label Press

| Maks.ukuran printing | 320 * 350 mm |

| Maks.Die cutter ukuran | 320 * 350 mm |

| Jembaré kertas | 100-330 mm |

| Ketebalan substrat | 80-300g/m2 |

| Baleni dawa | 100-350 mm |

| Pencet kacepetan | 30-180rpm (50m/min) |

| Rating motor | 30kw/6 warna |

| daya | 380V, 3 fase |

| Persyaratan pneumatik | 7 kg/cm2 |

| piring | Plat PS Kab |

| Ketebalan plat PS | 0,24 mm |

| Alkohol | 12%-10% |

| banyu | Sekitar 90% |

| Suhu banyu | 10 ℃ |

| Printing Cylinder Diameter | 180 mm |

| Lambaran karet | 0,95 mm |

| Karet Tinta | 23 bêsik |

| Karet Kesan | 4 pc |

| kacepetan maksimum | 8000 lembar / jam |

| Ukuran kacepetan maksimal | 720 * 1040 mm |

| Min ukuran sheet | 390 * 540 mm |

| Area cetak maksimal | 710 * 1040 mm |

| Ketebalan (bobot) kertas | 0,10-0,6 mm |

| Dhuwur tumpukan feeder | 1150 mm |

| Dhuwur tumpukan pangiriman | 1100 mm |

| daya sakabèhé | 45kw |

| Dimensi sakabèhé | 9302 * 3400 * 2100 mm |

| Bobot reged | Udakara 12600kg |

5 warna + 1 flexo UV vanish + 1 pemotong mati putar

5 warna + Turn bar

6 werna

6 warna + 1 flexo UV vanish + 1 pemotong mati rotary

1 unit Flexo + 5 warna + 1 flexo UV vanish + 1 pemotong mati rotary

6 warna + 1 cold foil + 1 flexo UV vanish + 1 rotary die cutter

7 warna + 1 flexo UV vanish + 1 pemotong mati rotary

| ●SISTEM KONTROL | ||

| Katrangan | Cathetan | Jeneng merek |

| Sistem kontrol komputer | Sistem kontrol multi-axis | Trio---------UK |

| Layar tutul kanggo mesin utama | 12 inch, macem-macem warna | Proface-----Jepang |

| PLC |

| Mitsubishi---Jepang |

| modul ekstensi PLC |

| Mitsubishi---Jepang |

| Konverter frekuensi | 400W | Mitsubishi---Jepang |

| Konverter frekuensi | 750W | Mitsubishi---Jepang |

| Coder |

| Omron------- Jepang |

| Ngalih, Tombol |

| Fuji---------- Jepang Schneider---Prancis |

| Kontaktor

| Simon-----Jerman | |

| Modul analog

|

| Mitsubishi---Jepang |

| Ngalih sumber daya |

| Meanwell----Taiwan |

| Steker penerbangan lan blok terminal |

| Hangke----Taiwan |

| ● Saben UNIT PRINTING | ||

| Katrangan | Cathetan | Jeneng merek |

| Servo motor | 3KW | Panasonic-----Jepang |

| Driver motor servo | Panasonic-----Jepang | |

| Ngurangi kacepetan | APEX---------- Taiwan | |

| Konverter frekuensi | Mitsubishi----Jepang | |

| Detektor jarak | Omron--------- Jepang | |

| silinder hawa | SMC------------ Jepang | |

| Tuntunan Lurus | HIWIN-------Taiwan | |

| Lacak Rapid-travel motor | 200W | Jingyan------Taiwan |

| Ngurangi kacepetan | Jingyan------Taiwan | |

| Karet tinta | Basch-------- Shanghai | |

| Coder | Omron------- Jepang | |

| bantalan | NSK------- Jepang | |

| Limit switch | Omron----Jepang | |

| Roller tinta | BASCH------ Shanghai | |

| ●SISTEM MATERIAL FEEDING 1 | ||

| Katrangan | Cathetan | Jeneng merek |

| Servo motor | 3KW | Panasonic-----Jepang |

| Driver motor servo | Panasonic-----Jepang | |

| Decelerator khusus | APEX--------- Taiwan | |

| Photocell kanggo unwinder | Omron-------- Jepang | |

| 2nd pass sensor

|

| Lara----------Jerman

|

| silinder hawa

| SMC-------- Jepang | |

| ●SISTEM MATERIAL FEEDING 2 | ||

| Katrangan | Cathetan | Jeneng merek |

| Motor | 200W | Jingyan----Taiwan |

| Ngurangi kacepetan | Jingyan----Taiwan | |

| Konverter frekuensi | 200V / 0.4KW | Panasonic-----Jepang |

| ● SISTEM REWINDER | ||

| Katrangan | Cathetan | Jeneng merek |

| Rewinder motor | L28—750W—7.5S | Chenggang-----Taiwan |

| pompa periferal | Cina | |

| Konverter frekuensi |

| Panasonic-----Jepang |

| Ngalih | Schneider (Prancis) | |

| Rewinder sensor | Omron------- Jepang | |

| ●SISTEM WEB-PASSING | ||

| Katrangan | Cathetan | Jeneng merek |

| Servo motor | 3KW | Panasonic-----Jepang |

| Driver motor servo | Panasonic-----Jepang | |

| Ngurangi kacepetan | APEX-------- Taiwan | |

| silinder hawa | SMC---------- Jepang | |

1) Servo mimpin: Sistem servo mimpin Independent ing saben unit kanggo njamin ndhaftar stabil ing kacepetan printing dhuwur.

2) Unit Printing: Gunakake sistem inking paling majeng kang wis 23 inking nggulung, papat gedhe diameteripun nggulung wangun klebu lan alkohol damping sistem kanggo njamin kualitas printing.

3) Sistem pra-registrasi: Adhedhasar dawa printing, log data menyang stasiun kontrol geser, saben unit bakal otomatis diatur kanggo posisi siap.

4) Sistem Register: Saben unit printing bisa remot nyetel register kang kalebu lineal, lateral lan skewing tanpa mandeg penet kanggo irit wektu lan ngurangi sampah substrat.

5) Kontrol aliran balik vakum unwinding: Silinder aliran balik vakum kudu bisa nyegah goresan ing mburi label P / S sajrone gerakan intermiten.

6) Joystickless: Sistem operasi kanthi otomatis kalebu pangaturan tekanan, washup roll inking, kesan roller, lsp.

7) Gampang kanggo operate: Dilengkapi stasiun kontrol layar tutul ngusapake kang bisa obah watara kanggo nambah efficiency operator.

8) Ukuran Printing: Teknologi pattered kanggo nyilikake ukuran printing kanggo entuk ukuran luwih gedhe saka printing ukuran variabel.

9) Sistem kontrol: Aplikasi komponen elektronik saka merek internasional sing misuwur kanggo njamin operasi sing dipercaya jangka panjang.

10) Sistem pelumasan: Pelumasan otomatis terpusat.